Bending, shaping, and repairing aircraft metal requires incredible skill, but describing it on paper feels like trying to fold titanium with your bare hands. Your daily expertise with complex repairs and precise measurements deserves more than a basic skills list.

Are you struggling to showcase your specialized aircraft sheet metal work in a way that grabs attention? A well-crafted resume needs to demonstrate both your technical mastery and your contribution to aircraft safety and reliability.

Resume Target helps aircraft sheet metal mechanics translate hands-on expertise into powerful job-winning documents. This guide will show you exactly how to highlight your precision work, safety record, and technical abilities in a way that makes hiring managers take notice.

As the skilled artisans of aviation maintenance, Aircraft Sheet Metal Mechanics are the masters of precision who plan, lay out, fabricate, assemble, install, and repair aircraft sheet metal parts that keep planes flying safely through the skies.

Your expertise as an Aircraft Sheet Metal Mechanic involves interpreting complex blueprints, shaping specialized materials with precise measurements, and using sophisticated fabrication equipment to create and repair critical aircraft components that must meet exact aviation safety standards.

If you're fascinated by both aviation and hands-on craftsmanship, the career path of an Aircraft Sheet Metal Mechanic offers exciting opportunities to advance from entry-level positions to senior specialist roles, where you'll tackle increasingly complex aircraft structures and potentially lead teams of aviation maintenance professionals.

Let's talk about the exciting earning potential in aircraft sheet metal work! Your career as an Aircraft Sheet Metal Mechanic can offer compelling compensation, with opportunities to increase your earnings through certifications, specialized education, and valuable experience. The field rewards skilled professionals who maintain and repair aircraft structures with competitive salaries that reflect their expertise.

Figures from: Salary.com

Start your journey as an Aircraft Sheet Metal Helper and climb the ranks to become a Senior Sheet Metal Mechanic. With dedication and skill development, you can advance to leadership positions in aircraft maintenance.

To accelerate your career growth, you'll need to master both technical expertise and essential soft skills that set you apart in the aviation industry.

- Advanced riveting and welding techniques - CAD software proficiency - Quality assurance and inspection expertise - Problem-solving and attention to detailLaunch your aircraft maintenance career by combining hands-on technical training with FAA certification programs to become a qualified sheet metal mechanic working on commercial and military aircraft.

To succeed in this field, you'll need to develop expertise in aircraft sheet metal techniques, including riveting, welding, and bonding, which you can gain through entry-level positions and apprenticeships.

Requirements from SpaceTEC

From aviation hubs to military bases, sheet metal mechanics find opportunities across specialized regions and industries.

Figures from DataUSA.io

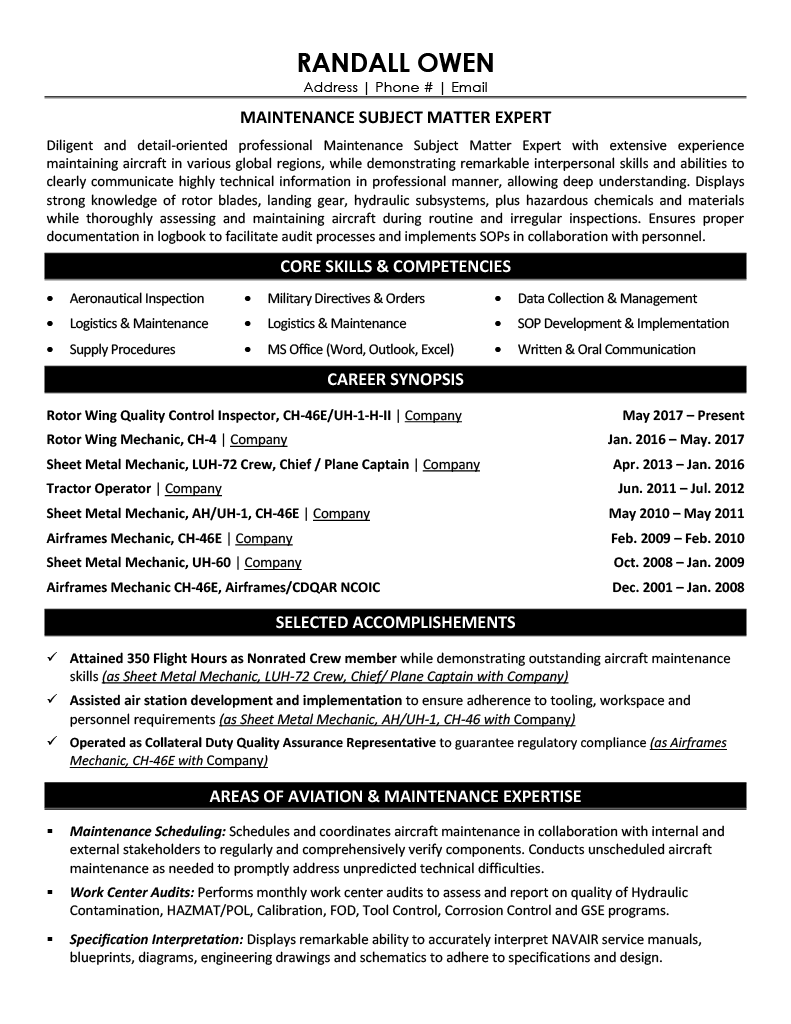

Struggling to showcase your sheet metal expertise, aircraft maintenance skills, and precision work in a way that catches employers' attention? This comprehensive, section-by-section guide will help you craft a professional resume that highlights your technical abilities and accomplishments in aircraft structural repair.

If you're like most Aircraft Sheet Metal Mechanics, crafting the perfect resume summary feels as challenging as fabricating a complex airframe component without blueprints.

While you excel at precision metalwork, structural repairs, and maintaining airworthiness standards, translating these hands-on skills into compelling written statements can leave even the most experienced aviation technician feeling grounded.

How would you characterize your overall expertise in aircraft sheet metal fabrication, repair, and modification across different aircraft types and materials?

Reason: This helps establish your broad technical foundation and versatility in the field, allowing you to craft a summary that immediately communicates your scope of expertise to hiring managers.

What would you say sets you apart from other sheet metal mechanics in terms of your specialized skills, certifications, or approach to aircraft structural integrity?

Reason: This question helps you identify and articulate your unique value proposition, enabling you to create a summary that distinguishes you from other candidates in the aviation maintenance field.

How would you describe your overall contribution to aircraft safety and maintenance efficiency throughout your career as a sheet metal mechanic?

Reason: This helps you frame your professional impact in terms that matter most to aviation employers - safety and efficiency - allowing you to craft a summary that resonates with industry priorities.

As an aircraft sheet metal mechanic, your skills section needs to demonstrate both your precision fabrication abilities and your understanding of aviation safety standards and regulations.

From specialized tools and equipment operation to blueprint interpretation and quality control procedures, you'll need to showcase both your technical expertise in metal forming and your daily maintenance capabilities.

Showcase your precision metalworking expertise by organizing your experience into three powerful sections: a concise role overview highlighting your aircraft systems knowledge, measurable achievements demonstrating your repair and fabrication successes, and core responsibilities that spotlight your technical capabilities.

Many Aircraft Sheet Metal Mechanics struggle to translate their hands-on technical expertise and precision work into compelling resume achievements that catch hiring managers' attention. Transform your daily repairs and modifications into powerful metrics by highlighting safety compliance rates, repair turnaround times, and cost savings that demonstrate your direct impact on aircraft operational readiness.

The responsibilities section demonstrates how Aircraft Sheet Metal Mechanics maintain aircraft structural integrity beyond basic repairs. Your duties should showcase technical expertise while clearly explaining complex metalwork processes to hiring managers, connecting your skills to overall aircraft safety and operational efficiency.

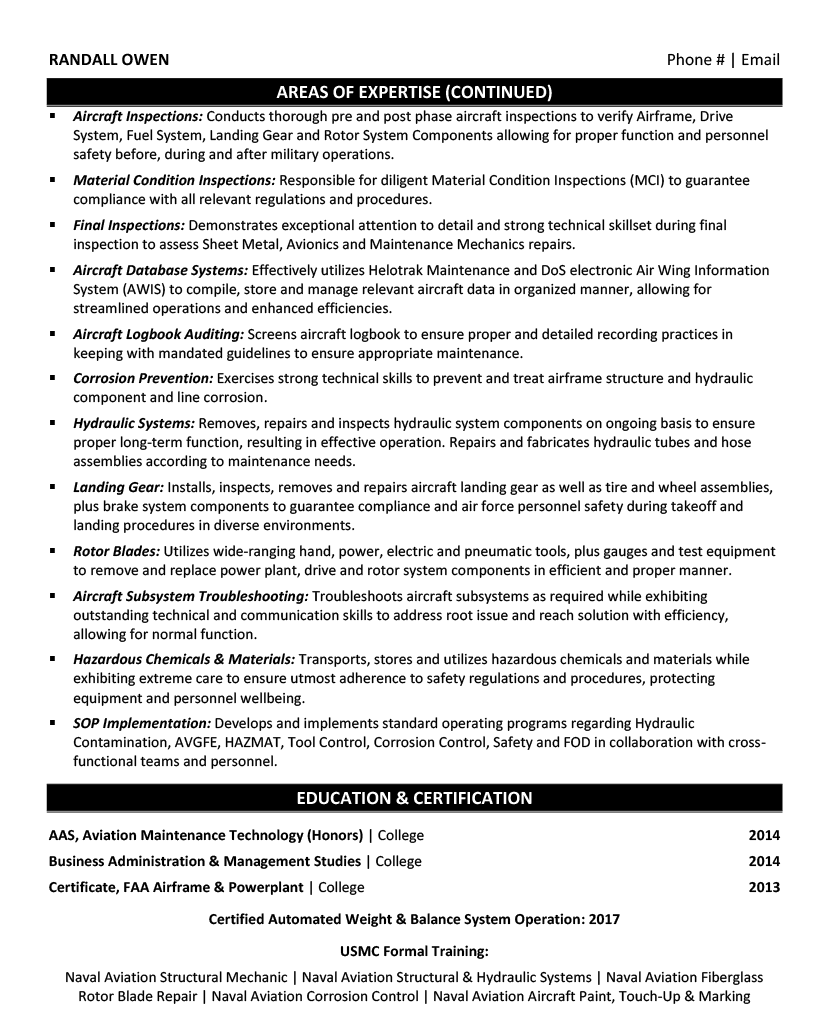

Your aircraft sheet metal training and certifications are crucial for demonstrating your expertise in airframe structural repair and fabrication. Focus on highlighting your FAA certifications, specialized training programs, and any relevant education that showcases your knowledge of aircraft metalworking, blueprint reading, and precision measurement skills.

Now that you've built a strong foundation using Resume Target's expert guidelines for resume writing, you're ready to transform your base resume into a powerful tool for landing your ideal aircraft sheet metal position.

While many mechanics focus solely on customizing their cover letters, tailoring your resume for specific aircraft sheet metal roles is equally crucial for showcasing your specialized skills and experience with specific aircraft types and repair techniques.

A customized resume helps you sail through ATS systems by incorporating the right industry-specific keywords, while simultaneously demonstrating to hiring managers that your sheet metal fabrication and repair expertise perfectly aligns with their maintenance operation's needs.

Ready to make your resume work harder for you? Let's transform your standard resume into a laser-focused document that proves you're the expert aircraft sheet metal mechanic they've been searching for!

Don't let a lack of professional experience ground your aviation career dreams! Your journey to becoming an Aircraft Sheet Metal Mechanic can take flight by showcasing your technical training, hands-on coursework, and relevant certification progress.

Focus your resume on highlighting your mechanical aptitude, blueprint reading abilities, and practical workshop experience.

For a complete breakdown of how to present your skills effectively, check out the Student Resume Writing Guide to ensure your application soars above the competition.

Your resume summary is your chance to showcase your technical training, hands-on projects, and aviation maintenance certifications that make you a promising candidate.

Focus on highlighting your precision skills, safety consciousness, and practical experience from your training program to demonstrate your readiness for this specialized role.

"Detail-oriented and safety-focused Aircraft Sheet Metal Mechanic with comprehensive technical training and hands-on experience through aviation maintenance program. Proficient in blueprint reading, metal fabrication techniques, and precision measuring tools, with demonstrated expertise in aircraft structural repair projects. Holds current A&P certification and maintains perfect safety record during training. Seeking to apply strong technical foundation and mechanical aptitude to contribute to an established aviation maintenance team."

Now's your chance to showcase the specialized training and certifications that make you a qualified aircraft sheet metal professional!

Don't just list your technical school diploma - highlight specific coursework in metallurgy, blueprint reading, and aircraft structures, plus include hands-on projects like fuselage panel repairs or rivet installations that demonstrate your practical skills.

Insufficient data available despite thorough search.Relevant Coursework: Aircraft Sheet Metal Fabrication | Blueprint Reading & Technical Drawing | Metallurgy Fundamentals | Aircraft Structural Repair | Precision Measurement & Quality Control | Aviation Safety Standards

Key Projects:

Aircraft Panel Repair Simulation: Completed comprehensive repair project on damaged aircraft fuselage panel, demonstrating proficiency in assessment, repair planning, and execution of sheet metal work.

Team Structural Component Fabrication: Led three-person team in designing and fabricating aircraft interior support structures to meet specific load-bearing requirements.

Leverage your technical training, hands-on experience from vocational programs, and aviation maintenance knowledge to create a compelling skills section that showcases your readiness for aircraft sheet metal work.

As an entry-level Aircraft Sheet Metal Mechanic, your foundation in essential technical skills and safety awareness positions you well for a growing career in aviation maintenance, where skilled professionals are increasingly in demand.

Let's face it - translating your hands-on expertise with complex aircraft structures into words that hiring managers understand can feel as challenging as precision riveting in tight spaces.

At Resume Target, we specialize in crafting resumes for aerospace professionals just like you, highlighting your technical prowess with sheet metal fabrication, repairs, and modifications in language that resonates with both hiring managers and ATS systems.

Our proven track record includes helping countless aircraft mechanics showcase their specialized skills, resulting in interviews at top aerospace companies and MRO facilities.

With major airlines and manufacturers ramping up their maintenance operations, now is the perfect time to upgrade your resume - connect with us today to ensure your expertise shines through.

Impress any hiring manager with our aviation resume writing service. We work with all career levels and types of aviation professionals.

Learn More → Aviationg Resume Writing Services