Instrumentation Technician

Resume Sample

A real resume example showing how we transform I&C expertise into proof maintenance managers trust

Being qualified isn't enough — you need to be the obvious choice.

We fix your resume with one conversation

What Makes a Strong Instrumentation Technician Resume?

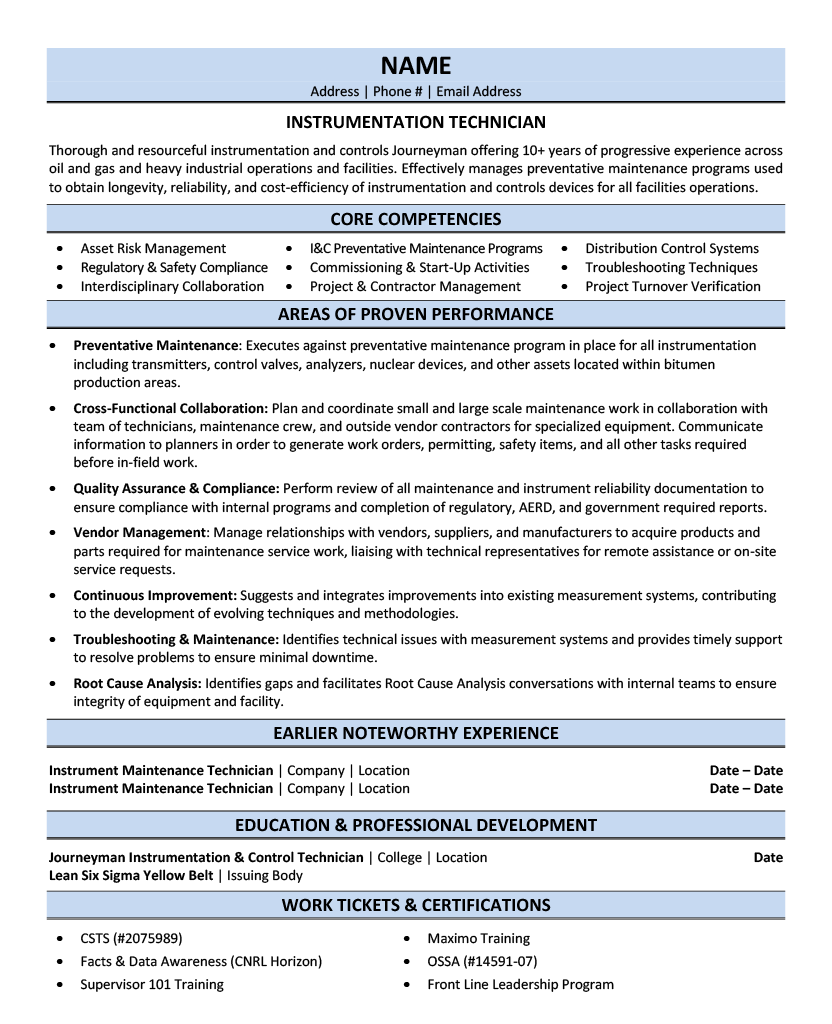

An Instrumentation Technician resume must prove ability to manage preventative maintenance programs, troubleshoot complex systems, and ensure regulatory compliance. Maintenance managers scan for Journeyman certification, equipment diversity, and continuous improvement mindset. This sample demonstrates Journeyman status with 10+ years progressive experience, preventative maintenance for transmitters, control valves, analyzers, and nuclear devices, Root Cause Analysis facilitation with internal teams, regulatory compliance including AERD and government required reports, and Lean Six Sigma Yellow Belt certification.

Why Do Instrumentation Technician Resumes

Get Rejected?

Most instrumentation technician resumes get rejected not because of ATS software, but because they don't prove you're better than the other 37 applicants. Generic bullets like "managed construction projects" don't differentiate you — quantified achievements do.

See how we transform generic statements into interview-winning proof:

We showed equipment diversity (transmitters, control valves, analyzers, nuclear devices), production context (bitumen production areas), and compliance scope (regulatory, AERD, government reports). Comprehensive equipment coverage demonstrates senior-level capability.

We showed coordination scope (small and large scale), team diversity (technicians, maintenance crew, vendor contractors), and vendor management (suppliers, manufacturers, technical representatives). Vendor relationship management demonstrates business capability.

We showed troubleshooting outcome (minimal downtime), analytical approach (Root Cause Analysis), and continuous improvement (integrates improvements, evolving methodologies). RCA facilitation demonstrates leadership beyond hands-on technical work.

How Do Oil & Gas Resume Writers Transform a Instrumentation Technician Resume?

Professional resume writers transform instrumentation technician resumes by analyzing job postings for required keywords, extracting specific achievements through targeted questions, quantifying impact with dollar values and percentages, and positioning you as the solution to employer problems.

We Analyze Instrumentation Technician Job Postings

We identify exactly what hiring managers search for:

- Budget management and cost control requirements

- Schedule recovery and timeline management skills

- Site safety compliance and OSHA standards

- Subcontractor coordination and vendor management

We Extract Your Achievements

Our 1-on-1 interview uncovers:

- Project values and budgets you've managed

- Team sizes and subcontractors you've coordinated

- Problems you've solved that others couldn't

- Metrics you didn't think to track or quantify

We Quantify Your Impact

We find the numbers that prove ROI:

- Dollar values of projects completed on time

- Percentage of schedule improvements achieved

- Cost savings from value engineering decisions

- Safety record improvements and incident reductions

We Position You as the Solution

Your resume proves you solve employer problems:

- Delivering projects on time despite site challenges

- Managing subcontractors and maintaining quality

- Controlling costs while meeting specifications

- Leading teams through complex project phases

Listen to a Real Resume Interview

Hear how our writers extract technical achievements from instrumentation professionals.

What Does a Instrumentation Technician Resume Interview Look Like?

A instrumentation technician resume interview is a conversation where our writer asks targeted questions about your projects, probes for specific details, and extracts achievements you'd never think to include.

Executes against preventative maintenance program in place for all instrumentation including transmitters, control valves, analyzers, nuclear devices, and other assets located within bitumen production areas. Perform review of all maintenance and instrument reliability documentation to ensure compliance with internal programs and completion of regulatory, AERD, and government required reports.

Every bullet on this resume was created through this same process.

Schedule Your InterviewHave questions? 1-877-777-6805

Watch How We Transformed This Technical Resume

See how our interview process uncovered preventative maintenance and continuous improvement achievements.

Get Your Resume Transformed

What a Instrumentation Technician Resume Example That Gets Interviews Looks Like

A complete instrumentation technician resume is typically 2 pages and includes a professional summary, core competencies, detailed work experience with quantified achievements, education, and certifications. Here's both pages of an actual resume created through our interview process.

Which Instrumentation Technician Resume Example

Do You Need?

The instrumentation technician resume you need depends on your career stage:

Senior Technician or Lead Position

Your resume needs to prove Journeyman certification, diverse equipment experience, and troubleshooting capability.

Questions We Ask in Your Interview:

- What equipment have you maintained?

- What troubleshooting have you done?

What We Highlight on Your Resume:

- Equipment diversity (transmitters, valves, analyzers)

- Troubleshooting and minimal downtime achievement

Supervisor or Specialist Transition

Your resume needs to differentiate you through continuous improvement, vendor management, and Root Cause Analysis leadership.

Questions We Ask in Your Interview:

- What improvements have you implemented?

- What Root Cause Analysis have you led?

What We Highlight on Your Resume:

- Continuous improvement and methodology development

- Root Cause Analysis and vendor management

How Do You Write a Instrumentation Technician Resume That Gets Interviews?

To write a instrumentation technician resume that gets interviews, focus on four key sections:

- Professional Summary — highlighting your experience level and specialty areas

- Skills Section — matching keywords from your target job postings

- Work Experience — quantified achievements using the Problem-Solution-Result format

- Credentials — relevant certifications and education

Most instrumentation technician resumes list equipment maintained without demonstrating preventative maintenance program ownership or continuous improvement contribution. Our interview process extracts the compliance activities, Root Cause Analysis leadership, and vendor management that prove you can ensure equipment reliability.

What Should an Instrumentation Technician Put in Their Profile Summary?

Your summary must signal both trade qualification and program ownership. This technician describes "Journeyman offering 10+ years of progressive experience across oil and gas and heavy industrial operations" who "effectively manages preventative maintenance programs used to obtain longevity, reliability, and cost-efficiency."

Lead with Journeyman status and years of experience. Highlight oil and gas and heavy industrial experience. Emphasize preventative maintenance program management, longevity, reliability, and cost-efficiency outcomes.

For apprentices or junior technicians seeking Journeyman roles...

Expert Questions We Ask:

- "What equipment have you maintained?"

- "What troubleshooting have you done?"

For Journeymen targeting supervisor or specialist roles...

Expert Questions We Ask:

- "What improvements have you implemented?"

- "What RCA have you led?"

What Skills Should an Instrumentation Technician Highlight?

Skills must show both technical capability and business awareness. This resume includes Asset Risk Management alongside Troubleshooting Techniques — demonstrating understanding of equipment criticality beyond just repair capability.

Include technical and business competencies: I&C Preventative Maintenance Programs, Commissioning & Start-Up Activities, Distribution Control Systems alongside Asset Risk Management, Regulatory & Safety Compliance, Project & Contractor Management. Add Troubleshooting Techniques and Project Turnover Verification.

Technical and troubleshooting skills establish foundation...

Expert Questions We Ask:

- "What systems can you troubleshoot?"

- "What control systems do you know?"

Management and compliance skills differentiate...

Expert Questions We Ask:

- "What contractor management have you done?"

- "What regulatory compliance?"

How Should an Instrumentation Technician Describe Their Experience?

Every competency area must show scope and impact. This resume shows specific equipment (transmitters, control valves, analyzers, nuclear devices), compliance requirements (regulatory, AERD, government reports), and outcomes (minimal downtime, evolving methodologies).

Organize by competency area rather than chronological bullets: Preventative Maintenance, Cross-Functional Collaboration, Quality Assurance & Compliance, Vendor Management, Continuous Improvement, Troubleshooting & Maintenance, Root Cause Analysis. Include specific equipment types and compliance requirements.

Show equipment diversity and troubleshooting capability...

Expert Questions We Ask:

- "What equipment have you maintained?"

- "What downtime have you prevented?"

Demonstrate improvement contribution and compliance leadership...

Expert Questions We Ask:

- "What improvements have you suggested?"

- "What RCA have you facilitated?"

What Credentials Matter for Instrumentation Technicians?

Credentials should show trade qualification plus growth mindset. This resume shows Journeyman Instrumentation & Control Technician plus Lean Six Sigma Yellow Belt and Front Line Leadership Program — demonstrating preparation for supervisory advancement.

Include Journeyman certification prominently. List continuous improvement credentials (Lean Six Sigma Yellow Belt) and industry safety tickets (CSTS, OSSA). Add specialized training (Maximo, Front Line Leadership Program) to show advancement readiness.

Journeyman certification and safety tickets establish eligibility...

Expert Questions We Ask:

- "Do you have Journeyman certification?"

- "Are safety tickets current?"

Leadership and improvement certifications differentiate...

Expert Questions We Ask:

- "Do you have Lean Six Sigma?"

- "What leadership training have you completed?"

Skip the guesswork — let our expert resume writers ask these questions for you.

Schedule Your Resume InterviewHow Does a Resume Interview Extract

Your Instrumentation Technician Achievements?

A professional resume interview extracts instrumentation technician achievements by probing into specific projects, uncovering the goals you were trying to achieve, documenting the systems and processes you implemented, and surfacing challenges you overcame.

What Projects Should You Include

on a Instrumentation Technician Resume?

Include projects that demonstrate scope, stakes, and significance. We probe to understand the project value, team size, and your specific role.

How Do You Show Business Impact

on a Resume?

Connect your work to business outcomes by documenting the company's objectives and how your contributions achieved them.

What Systems and Processes

Should You Highlight?

Document the specific systems, processes, and strategies you implemented. This is where your expertise becomes visible.

How Do You Present

Challenges Overcome?

Describe challenges you faced and how you solved them. Problem-solving examples prove you can handle obstacles.

The Power of a 1-on-1 Resume Interview

No cookie-cutter calls. Your interview length matches your career complexity. We ask the questions you can't ask yourself.

Telephone Interview

Telephone Interview

Telephone Interview

Telephone Interview

Telephone Interview

How Competitive Is the

Instrumentation Technician Job Market?

Instrumentation Technician jobs are moderately competitive, averaging 38 applicants per position. With most job seekers applying to 20+ roles, you're competing against approximately 760 candidates for the same jobs.

Instrumentation Technician Job

Jobs Posted (30 Days)

Per 20 Applications

Hardest to Land

Most competitive oil & gas rolesEasier to Land

Less competitive oil & gas rolesData based on LinkedIn job postings, updated January 2026. View full job market data →

Here's the math most job seekers don't do:

Your resume needs to stand out against 760 other oil & gas professionals.

Most of them list the same projects. The same certifications. The same responsibilities.

What makes you different is the story behind the projects.

Oil & Gas Professionals We've Helped Are Now Working At

From general contractors to specialty trades, our clients land roles at top oil & gas firms across North America.

Reach Oil & Gas's Hidden Job Market

80% of oil & gas positions are never advertised. Get your resume directly into the hands of recruiters filling confidential searches.

Oil & Gas Recruiter Network

When you purchase our Resume Distribution service, your resume goes to 220+ recruiters specializing in oil & gas — included in Advanced & Ultimate packages.

Spencer Ogden

Houston, TX

Airswift

Calgary, AB

Sample Oil & Gas Recruiters

220+ Total| Agency | Location |

|---|---|

SO Spencer Ogden |

Houston, TX |

AS Airswift |

Calgary, AB |

NF NES Fircroft |

Houston, TX |

Frequently Asked Questions About

Instrumentation Technician Resumes

Your resume must demonstrate Journeyman certification, equipment diversity, and preventative maintenance capability. Include specific equipment maintained (this sample shows transmitters, control valves, analyzers, nuclear devices), compliance activities (regulatory, AERD, government reports), and continuous improvement involvement (Root Cause Analysis, methodology development).

The instrumentation technician market shows 38 applicants per position. Demand is strong in oil sands and petrochemical sectors. Journeyman certification, nuclear device experience, and Lean Six Sigma credentials differentiate significantly.

Include technical and process skills: I&C Preventative Maintenance Programs, Commissioning & Start-Up Activities, Distribution Control Systems alongside Asset Risk Management, Regulatory & Safety Compliance, Troubleshooting Techniques. Add Project Turnover Verification for capital project experience.

List specific instrument types maintained. This resume shows "transmitters, control valves, analyzers, nuclear devices, and other assets located within bitumen production areas." Specific equipment types plus production context (bitumen) demonstrates industry-specific expertise.

Absolutely — RCA demonstrates analytical capability. This resume shows "Identifies gaps and facilitates Root Cause Analysis conversations with internal teams to ensure integrity of equipment and facility." Facilitating RCA (not just participating) demonstrates leadership beyond hands-on work.

Include trade certification and safety tickets. This resume shows Journeyman Instrumentation & Control Technician, Lean Six Sigma Yellow Belt, CSTS, OSSA, Maximo Training, Front Line Leadership Program. Lean Six Sigma plus leadership training shows advancement readiness beyond technical capability.

Ready to Transform Your Resume?

Schedule your 45-minute interview and get a resume that proves you're the obvious choice.

Choose Your Interview LengthHave Questions?

Talk to an advisor who can recommend the right package for your situation.

Talk to an Advisor 1-877-777-6805