Production Planner

Resume Sample

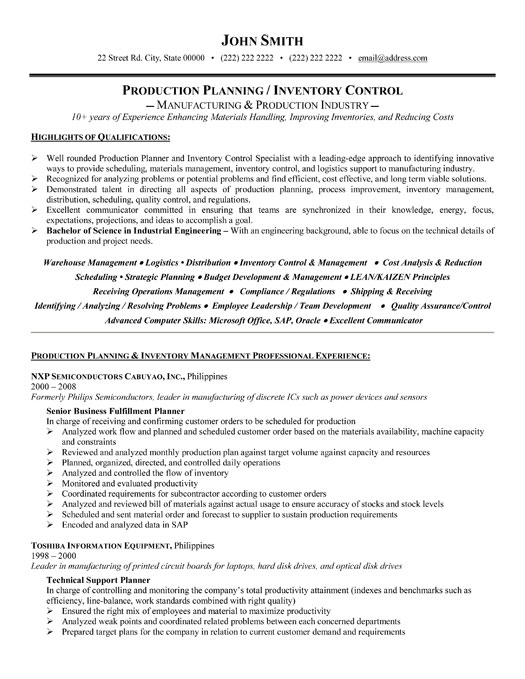

A real resume example showing how we transform inventory control and LEAN manufacturing expertise into proof employers trust

Being qualified isn't enough — you need to be the obvious choice.

We fix your resume with one conversation

What Makes a Strong Production Planner Resume?

A Production Planner resume must prove you can balance production schedules with inventory optimization while hitting delivery targets. Hiring managers scan for ERP proficiency (SAP, Oracle), LEAN/KAIZEN methodology experience, and measurable productivity improvements. This sample demonstrates how interview-extracted achievements showcase capacity planning and cross-functional coordination expertise.

Why Do Production Planner Resumes

Get Rejected?

Most production planner resumes get rejected not because of ATS software, but because they don't prove you're better than the other 44 applicants. Generic bullets like "managed construction projects" don't differentiate you — quantified achievements do.

See how we transform generic statements into interview-winning proof:

Reviewed and analyzed monthly production plan against target volume against capacity and resources."

This bullet demonstrates analytical capability and systematic approach to capacity planning. It shows the candidate understands the multiple variables that affect production scheduling and can make data-driven decisions. ATS systems pick up keywords like "production plan," "capacity," and "scheduled."

Analyzed and reviewed bill of materials against actual usage to ensure accuracy of stocks and stock levels."

This shows proactive inventory management rather than reactive firefighting. The specific mention of bill of materials analysis demonstrates technical depth, while "ensure accuracy" speaks to quality control mindset. Manufacturing hiring managers value candidates who prevent problems rather than just solve them.

Ensured the right mix of employees and material to maximize productivity."

This bullet quantifies the scope of responsibility (total productivity) while demonstrating understanding of multiple efficiency metrics. The phrase "right mix of employees and material" shows resource optimization skills. It positions the candidate as someone who sees the big picture of manufacturing operations, not just individual tasks.

How Do Supply Chain Resume Writers Transform a Production Planner Resume?

Professional resume writers transform production planner resumes by analyzing job postings for required keywords, extracting specific achievements through targeted questions, quantifying impact with dollar values and percentages, and positioning you as the solution to employer problems.

We Analyze Production Planner Job Postings

We identify exactly what hiring managers search for:

- Budget management and cost control requirements

- Schedule recovery and timeline management skills

- Site safety compliance and OSHA standards

- Subcontractor coordination and vendor management

We Extract Your Achievements

Our 1-on-1 interview uncovers:

- Project values and budgets you've managed

- Team sizes and subcontractors you've coordinated

- Problems you've solved that others couldn't

- Metrics you didn't think to track or quantify

We Quantify Your Impact

We find the numbers that prove ROI:

- Dollar values of projects completed on time

- Percentage of schedule improvements achieved

- Cost savings from value engineering decisions

- Safety record improvements and incident reductions

We Position You as the Solution

Your resume proves you solve employer problems:

- Delivering projects on time despite site challenges

- Managing subcontractors and maintaining quality

- Controlling costs while meeting specifications

- Leading teams through complex project phases

Listen to a Real Resume Interview

Hear how our writers extract production planning achievements through targeted questions.

What Does a Production Planner Resume Interview Look Like?

A production planner resume interview is a conversation where our writer asks targeted questions about your projects, probes for specific details, and extracts achievements you'd never think to include.

Analyzed work flow and planned and scheduled customer orders to be scheduled for production based on the materials availability, machine capacity and constraints.

Reviewed and analyzed monthly production plan against target volume against capacity and resources.

Every bullet on this resume was created through this same process.

Schedule Your InterviewHave questions? 1-877-777-6805

Watch How We Transformed Khoi's Resume

See how our interview process uncovered achievements that generic templates miss.

Get Your Resume Transformed

What a Production Planner Resume Example That Gets Interviews Looks Like

A complete production planner resume is typically 1-2 pages and includes a professional summary, core competencies, detailed work experience with quantified achievements, education, and certifications. Here's an actual resume created through our interview process.

Which Production Planner Resume Example

Do You Need?

The production planner resume you need depends on your career stage:

Career Advancement

Your resume needs to prove readiness for demand forecasting, capacity analysis, and cross-departmental coordination.

Questions We Ask in Your Interview:

- Have you worked with production schedules or capacity constraints in your current role?

- What ERP systems have you used for inventory tracking or order management?

What We Highlight on Your Resume:

- Exposure to production workflows and scheduling concepts

- Data analysis experience with inventory systems or Excel

- Coordination between departments or with suppliers

Senior Transition

Your resume needs to differentiate you through strategic impact on productivity metrics, cost reduction, and process optimization leadership.

Questions We Ask in Your Interview:

- What production volume or inventory value have you been responsible for planning?

- How have your LEAN initiatives or process improvements affected company KPIs?

What We Highlight on Your Resume:

- Productivity improvements with specific percentage gains

- LEAN/KAIZEN implementation across multiple production lines

- Cross-functional leadership in S&OP or demand planning processes

How Do You Write a Production Planner Resume That Gets Interviews?

To write a production planner resume that gets interviews, focus on four key sections:

- Professional Summary — highlighting your experience level and specialty areas

- Skills Section — matching keywords from your target job postings

- Work Experience — quantified achievements using the Problem-Solution-Result format

- Credentials — relevant certifications and education

Most "how to write a resume" guides give you generic templates. We interview you to extract specific achievements. Here's what we focus on for Production Planners:

What Should a Production Planner Put in Their Professional Summary?

Your summary must signal both your technical depth in production planning and your ability to drive measurable improvements. Generic summaries like "detail-oriented planner" don't differentiate you from hundreds of other candidates.

Include years of manufacturing experience, industry specialization (semiconductor, automotive, FMCG), production volume you've planned, ERP systems you've mastered, and key methodology expertise like LEAN/KAIZEN.

For those moving into Production Planner roles from coordinator or analyst positions:

Expert Questions We Ask:

- "Have you created or modified production schedules, even informally or during coverage?"

- "What data analysis have you done related to capacity, inventory, or production output?"

For experienced Production Planners targeting senior or management roles:

Expert Questions We Ask:

- "What's the largest production volume or product mix you've been responsible for planning?"

- "How have your planning decisions directly impacted company KPIs like OTD, inventory turns, or production costs?"

What Skills Should a Production Planner Highlight?

Your skills section must mirror the language in job postings. ATS systems filter for specific terms, so "SAP Production Planning" matters more than just "SAP experience."

Lead with ERP systems (SAP PP, Oracle, JD Edwards), then production planning specifics (MRP, capacity planning, demand forecasting), followed by methodologies (LEAN, KAIZEN, Six Sigma), and round out with soft skills (cross-functional coordination, vendor management).

Technical skills are your entry point—show what systems and tools you can operate:

Expert Questions We Ask:

- "Which ERP transactions or modules have you worked with, even if in a support role?"

- "Have you used Excel for capacity analysis, forecasting, or production tracking?"

Strategic and leadership skills differentiate senior candidates:

Expert Questions We Ask:

- "Have you led S&OP processes or represented production planning in cross-functional meetings?"

- "What continuous improvement methodologies have you implemented or led?"

How Should a Production Planner Describe Their Experience?

Numbers matter more in production planning than almost any other field. Hiring managers want to know: How many units? What cycle time? How much inventory reduction? What OTD improvement?

Lead each bullet with scope (production volume, number of SKUs, team size) and end with measurable results. Show the complexity of what you planned—multiple production lines, multi-site coordination, or high-mix low-volume environments demonstrate advanced capability.

Show exposure to planning concepts even if you weren't the primary planner:

Expert Questions We Ask:

- "Have you covered for a planner during vacation or assisted with rush orders?"

- "What production metrics have you tracked or reported on?"

Demonstrate strategic impact beyond daily scheduling:

Expert Questions We Ask:

- "How have your planning decisions affected working capital through inventory optimization?"

- "What capacity expansion or new product introduction planning have you led?"

What Education Matters for Production Planners?

Certifications signal commitment to the profession and provide standardized vocabulary that hiring managers recognize. In a competitive market, CPIM or CSCP can be the differentiator between otherwise equal candidates.

Industrial Engineering, Supply Chain Management, Operations Management, or Business degrees are most relevant. APICS certifications (CPIM, CSCP) carry significant weight, as do Lean Six Sigma belts and ERP-specific certifications.

Entry certifications establish credibility when experience is limited:

Expert Questions We Ask:

- "Have you completed any APICS coursework or are you pursuing CPIM?"

- "What relevant coursework or training have you completed in production planning or supply chain?"

Advanced certifications and continuous learning differentiate senior candidates:

Expert Questions We Ask:

- "Do you have CPIM, CSCP, or Lean Six Sigma Black Belt certification?"

- "Have you trained others in planning methodologies or ERP systems?"

Skip the guesswork — let our expert resume writers ask these questions for you.

Schedule Your Resume InterviewHow Does a Resume Interview Extract

Your Production Planner Achievements?

A professional resume interview extracts production planner achievements by probing into specific projects, uncovering the goals you were trying to achieve, documenting the systems and processes you implemented, and surfacing challenges you overcame.

What Projects Should You Include

on a Production Planner Resume?

Include projects that demonstrate scope, stakes, and significance. We probe to understand the project value, team size, and your specific role.

How Do You Show Business Impact

on a Resume?

Connect your work to business outcomes by documenting the company's objectives and how your contributions achieved them.

What Systems and Processes

Should You Highlight?

Document the specific systems, processes, and strategies you implemented. This is where your expertise becomes visible.

How Do You Present

Challenges Overcome?

Describe challenges you faced and how you solved them. Problem-solving examples prove you can handle obstacles.

The Power of a 1-on-1 Resume Interview

No cookie-cutter calls. Your interview length matches your career complexity. We ask the questions you can't ask yourself.

Telephone Interview

Telephone Interview

Telephone Interview

Telephone Interview

Telephone Interview

How Competitive Is the

Production Planner Job Market?

Production Planner jobs are moderately competitive, averaging 45 applicants per position. With most job seekers applying to 20+ roles, you're competing against approximately 900 candidates for the same jobs.

Production Planner Job

Jobs Posted (30 Days)

Per 20 Applications

Here's the math most job seekers don't do:

Your resume needs to stand out against 900 other supply chain professionals.

Most of them list the same projects. The same certifications. The same responsibilities.

What makes you different is the story behind the projects.

Supply Chain Professionals We've Helped Are Now Working At

From general contractors to specialty trades, our clients land roles at top supply chain firms across North America.

Reach Supply Chain's Hidden Job Market

80% of supply chain positions are never advertised. Get your resume directly into the hands of recruiters filling confidential searches.

Supply Chain Recruiter Network

When you purchase our Resume Distribution service, your resume goes to 380+ recruiters specializing in supply chain — included in Advanced & Ultimate packages.

Manufacturing Recruiting Partners

Detroit, MI

Supply Chain Talent Solutions

Chicago, IL

Sample Supply Chain Recruiters

380+ Total| Agency | Location |

|---|---|

MRP Manufacturing Recruiting Partners |

Detroit, MI |

SCT Supply Chain Talent Solutions |

Chicago, IL |

ISE Industrial Staffing Experts |

Dallas, TX |

Frequently Asked Questions About

Production Planner Resumes

A strong Production Planner resume should highlight your ERP system expertise (SAP, Oracle, or similar), capacity planning experience, and inventory control skills. Include specific achievements like production schedule optimization, on-time delivery improvements, or inventory reduction percentages. Demonstrate your understanding of LEAN/KAIZEN methodologies and your ability to coordinate across departments including procurement, manufacturing, and shipping.

Production Planner roles see moderate to high competition, with manufacturing hubs like the Midwest, Texas, and Southeast having the strongest demand. Candidates with SAP or Oracle experience, LEAN certifications, and semiconductor or automotive industry background have advantages. The shift toward advanced manufacturing and reshoring has increased demand for experienced planners who can optimize complex supply chains.

The most valuable certifications include APICS CPIM (Certified in Production and Inventory Management), CSCP (Certified Supply Chain Professional), and Lean Six Sigma Green Belt or Black Belt. SAP certification in Materials Management (MM) or Production Planning (PP) modules also differentiates candidates. Industry-specific certifications in automotive (IATF 16949) or aerospace (AS9100) add value for those sectors.

Quantify your continuous improvement impact. Instead of listing "LEAN experience," specify what you improved and by how much: "Implemented KAIZEN events that reduced changeover time by 35%" or "Led LEAN initiative increasing line efficiency from 78% to 92%." Show your methodology knowledge through terms like cycle time reduction, value stream mapping, 5S implementation, or waste elimination.

Lead with your SAP PP (Production Planning) or Oracle Manufacturing experience if you have it—these are the most sought-after. Include specific modules you've worked with: MRP runs, capacity planning, demand management, or shop floor control. Mention your proficiency with production scheduling transactions, BOM management, and work order processing. Advanced Excel skills for capacity analysis remain important even with ERP expertise.

Emphasize any exposure to scheduling decisions, capacity constraints, or demand forecasting in your current role. Highlight cross-training with planners, participation in S&OP meetings, or projects where you analyzed production data. Show progressive responsibility: "Promoted from floor coordinator to assist senior planner with weekly scheduling during peak season." Any ERP experience—even running reports—should be prominently featured.

Ready to Transform Your Resume?

Schedule your 60-minute interview and get a resume that proves you're the obvious choice.

Choose Your Interview LengthHave Questions?

Talk to an advisor who can recommend the right package for your situation.

Talk to an Advisor 1-877-777-6805